Well, in this case, more than one.

Well, in this case, more than one.I rode over to the nearest town with a branch of my bank yesterday to deposit our tenant's rent check and, while stopped behind a panel truck, noticed my headlight's low beam was out.

I switched over to high beam and rode to an auto parts store where I dug out my owner's maintenance manual and determined I needed an H7 12v55w bulb.

I'd watched a BMW service technician change the bulb on a K1200RS a couple of weeks ago over at the Savoy, Ill., dealership and figured it wouldn't be much of a task.

So, with new bulb in hand, I shucked my jacket in the auto parts store parking lot and started poking around in the alarmingly small space under the fairing and behind the headlight.

The first obstacle was a wire bail that held a protective cover in place, kind of like the wire bail on a Ball mason jar. The manual advised to pull one corner down, and then the other. I pushed and tugged and sweated and swore and finally got out my cell phone and called the dealership to ask if it was okay to use a screwdriver or some other tool to pry it loose. I was told that no tool is necessary, and to just pull out and down. Yeah, right. I tried til my fingers hurt and then decided to ride on home and continue the project in my garage.

Back home, I went online and posted an appeal for help to the BMW Motorcycle Owners of America K-bike forum.

Minutes later, I had an answer from a friend in Chicago, who had even gone to the trouble of shooting a digital photo of the underside of his K1200LT headlight assembly. I noticed, with some chagrin, that the space behind the LT fairing is absolutely cavernous compared with my GT.

I decided to use the shaft of a short crescent wrench for leverage and sure enough, the bail released and the cover popped right off. After about 20 minutes of maneuvering, I had the cover out of the way and out of the fairing.

The next step was to pull the plug connector off of the bulb terminals. I found there was no way I could actually look at the parts while I worked on them, so it had to be done by feel. The bulb was also in a position where I could only get my fingers on the connector and other parts with my left hand.

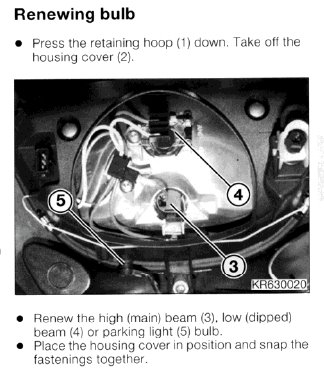

It only took a couple of minutes to get a grip on the connector plug and wiggle it loose. Then it was a matter of releasing the two wire retainer clips that hold the bulb in place. The illustration in the maintenance manual was devoid of fine detail, so I had to guess at how they worked and feel my way through releasing them and swinging them out of the way to the left.

The old dead bulb tumbled out and fell to the garage floor - a warning that I'd better take care not to drop the new bulb in the installation process.

I gingerly removed the new bulb from its package, being careful not to touch the glass with my fingers lest I leave an oil deposit that would make a fatal hot spot on the bulb. Noting that the guide flange points up in the bulb installation, I slipped the new bulb into place in the headlight shell and swung the two retainer clips around to latch it in.

But they wouldn't catch. I struggled blindly with them for more than an hour, sweating and cursing until my fingers hurt and my back ached.

I got out a powerful trouble light and peered into the tiny space between the handebars and the fairing. I studied it with the bulb in place and with the bulb removed. I found the clips snapped right into place with the bulb removed, but stubbornly refused to grip with the bulb in place.

Finally, I tried it with one finger of my right hand and I kinda felt like it fastened, but I couldn't be sure.

Fuck it, I thought. This is close enough.

So I put the connector plug onto the back of the hopefully secured bulb.

But try as I might, I couldn't figure out how to work the cover back into place from beneath the fairing. There's no way in hell it will fit coming in from the top and it's turned into some kind of a Chinese puzzle to get it up from the bottom.

When Maria got home from work, she tried her somewhat smaller hand at it, but quickly surrendered.

So I closed the garage door and concluded I'd gone as far as I could.

I was loathe to ride 100 miles to the Savoy, Ill., dealership and pay the $70/hour shop fee to finish the job, but it looked like that was how it would play out.

But sometime in the middle of the night, as I chewed on the problem between episodes of sleep, I remembered a couple of the guys who used to work at the Indianapolis BMW dealership were still around, working at a Triumph shop in Indy and they doubtless had experience with this problem.

So this morning I called my friend Wayne, who used to be parts manager at the Indy BMW shop, and told him of my problem. Wayne gave me the cell phone number of one of the guys and also offered to come up and help me after he got off work if I didn't get things sorted out by then. Good man, Wayne.

So I called Neil Baird's cell phone and left a voicemail plea for help and now I'm waiting for a callback with a flicker of hope in my heart.

And I will never fucking never attempt to change the headlight bulb on that bike again. Never.

-----------------------

Neil didn't return my call until the next day, so Wayne and his wife Peggy drove up and we struggled with the problem.

After much frustrating fumbling, we determined one of the retaining wires was bent, which was preventing it from latching properly. Wayne made the adjustment. We worked out a system where Wayne would sit on my mechanic's crawler stool in front of the bike, hands up the underside of the fairing, while I used a small but powerful trouble light to peer over the tank and under the bars and through an opening in the fairing to guide his fingers and a large flat-bladed screwdriver to force the upper retaining wire into its slot.

That done, Wayne spent about 15 minutes working the cover back up under the fairing to its proper place. Then we spent another 20 minutes or so blindly fumbling for the anchor holes for the two ends of the bail. We finally concluded it was impossible without being able to see more of the interior of the fairing, so Wayne removed the wind deflectors and a couple of interior fairing pieces that gave us a glimpse of the holes. With me holding the light and Maria holding the cover in place, Peggy hooked the bail into its holes and Wayne snapped it back up into place to secure the cover.

All told, counting everyone who participated, I calculate this project took about 8 man/woman hours. If we were making the standard shop rate of $70/hour, that translates to a $560 job. Just to change a light bulb.

When I talked to Neil the next day, he told me he and Bob Lustgarten, who had been a BMW service technician at Revard BMW Motorcycles, were planning to add BMW service to the Triumph dealership where they now work.

Neil said they expect to have the parts and equipment they need in a couple of weeks, after which time they will be able to perform non-warranty service like oil and tire changes, brake pad replacements, and the like.

So guess where I'm going the next time my headlight bulb fails.

1 comment:

THIS was great, the most hilarious story EVER!! I laughed out loud for real.

Thanks!!

Post a Comment